DOCUMENTATION

CONTEMPORARY FABRICATION

TECHNIQUES

DOCUMENTATION

NATALIE TAOUK

1. Peter Zumthor | Therme

Vals

|

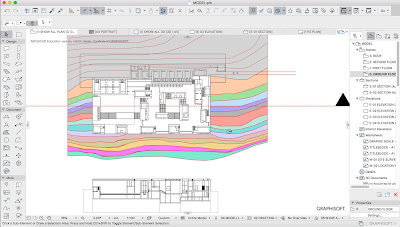

| Digital File |

Creating the digital model assisted with breaking down of the different model components.

|

| Contours |

|

| Roof + Wall units |

Assembling the pieces together...

|

| Base + Contours |

|

| Wall Units |

|

| Roof Structure |

|

| Wall + Roof assembly |

The pieces of timber were glued together layer

by layer, some of the units needed to be reassembled to get the geometry accurate.

2. Tietigen student dormitory | Lundgaard & Tranberg Architects

Space organisation diagrams

|

| Ground floor plan + Site plan |

|

| First floor plan + spacial arrangement + room layouts |

Preparing the digital file for laser cutting and engraving

Two materials were tested for this model, poplar plywood and

white acrylic sheets.

Experimenting with the two materials, the poplar plywood pieces

took much longer for the glue to dry, due to the nature of the material it was

difficult assemble the pieces as there were many pieces which needed to be slotted

into place. To achieve the desired finish white acrylic sheets was used to

represent the walls, columns and floor.

3. 600-610 Elizabeth Street Redfern |

Site Model

Two coats of Maple water based interior stain was used for the base finish.

Cover stain primer was used as an

undercoat to cover the burn stains on the laser cut basswood, by using a cover

stain as an under coat it saved time, only one coat of white spray paint was

required to get the desired finish.

Comments

Post a Comment